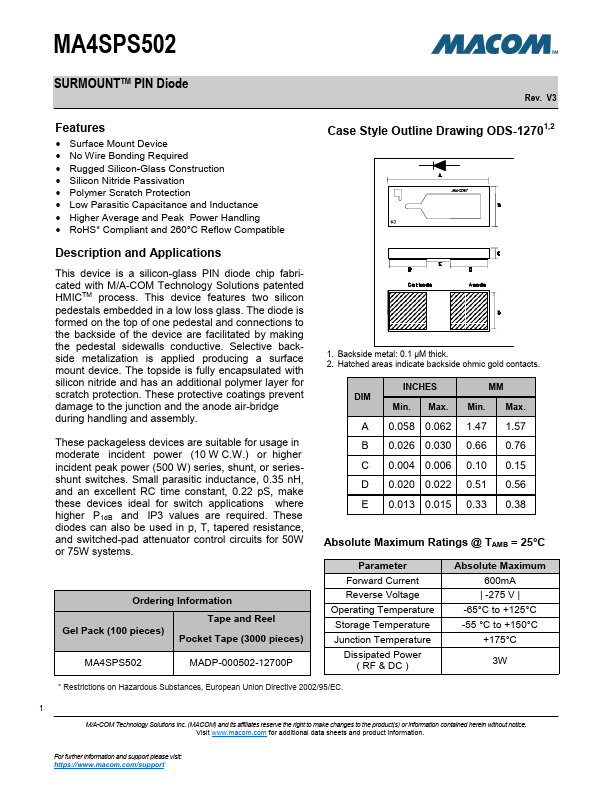

MA4SPS502 Description

and Applications This device is a silicon-glass PIN diode chip fabricated with M/A- Technology Solutions patented HMICTM process.

MA4SPS502 Key Features

- Surface Mount Device

- No Wire Bonding Required

- Rugged Silicon-Glass Construction

- Silicon Nitride Passivation

- Polymer Scratch Protection

- Low Parasitic Capacitance and Inductance

- Higher Average and Peak Power Handling

- RoHS- pliant and 260°C Reflow patible