PHR2010 Overview

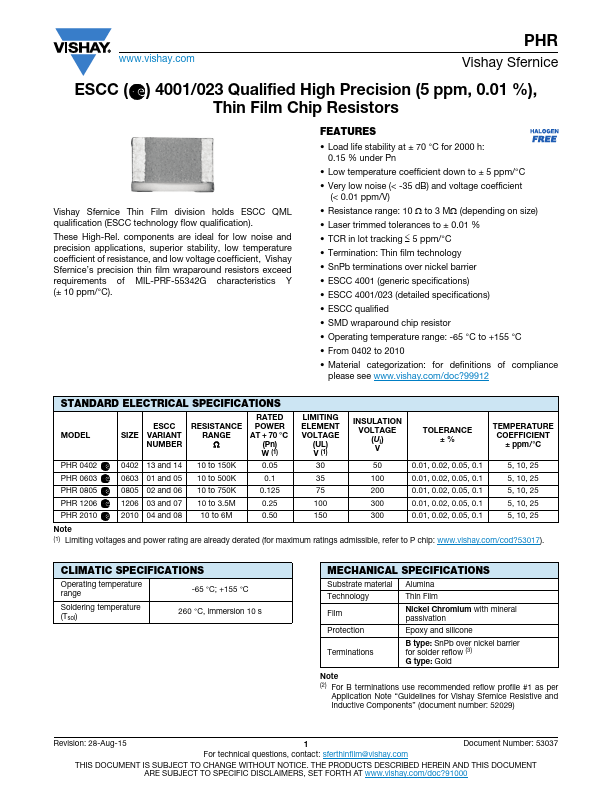

PHR Vishay Sfernice ESCC ( ) 4001/023 Qualified High Precision (5 ppm, 0.01 %), Thin Film Chip Resistors Vishay Sfernice Thin Film division holds ESCC QML qualification (ESCC technology flow qualification). ponents are ideal for low noise and precision applications, superior stability, low temperature coefficient of resistance, and low voltage coefficient, Vishay Sfernice’s precision thin film wraparound resistors...

PHR2010 Key Features

- Load life stability at ± 70 °C for 2000 h:

- Low temperature coefficient down to ± 5 ppm/°C

- Very low noise (< -35 dB) and voltage coefficient

- Resistance range: 10 to 3 M (depending on size)

- Laser trimmed tolerances to ± 0.01 %

- TCR in lot tracking 5 ppm/°C

- Termination: Thin film technology

- SnPb terminations over nickel barrier

- ESCC 4001 (generic specifications)

- ESCC 4001/023 (detailed specifications)

PHR2010 Applications

- Load life stability at ± 70 °C for 2000 h:

- Low temperature coefficient down to ± 5 ppm/°C