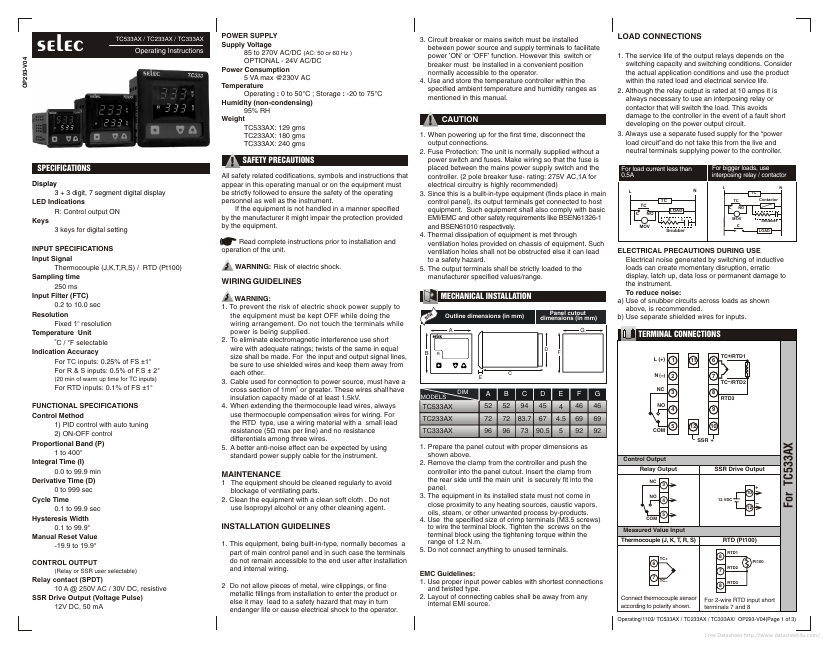

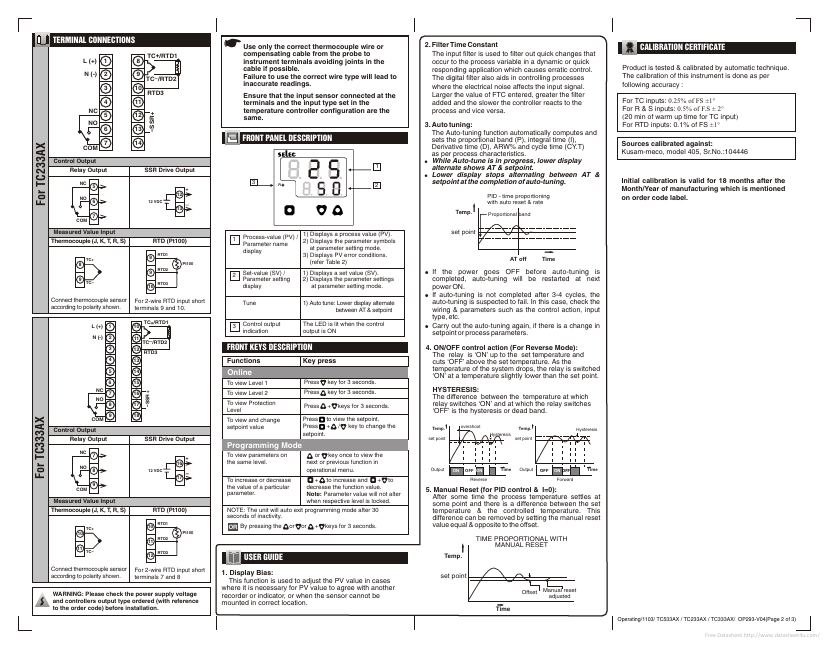

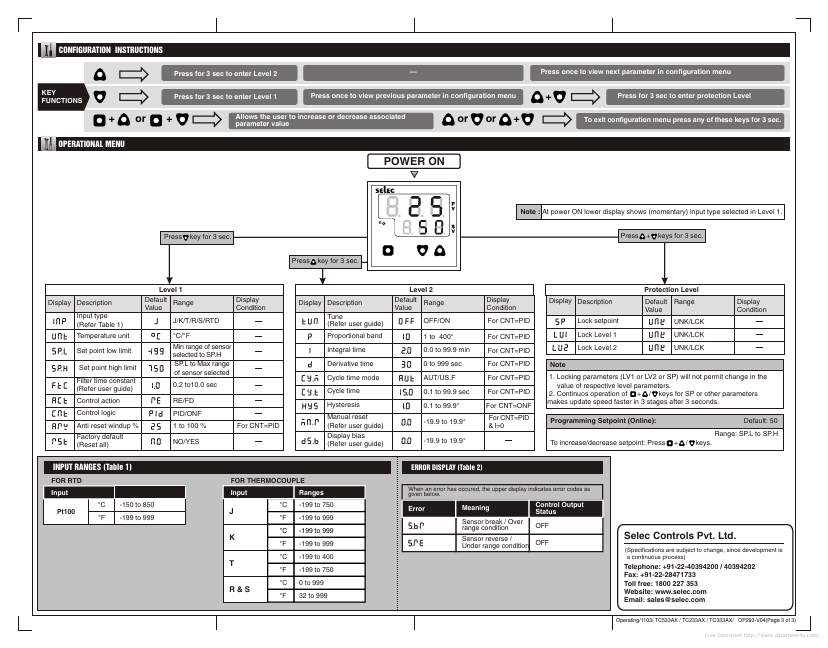

TC233AX Overview

selec OP293-V04 TC533AX / TC233AX / TC333AX Operating Instructions POWER SUPPLY Supply Voltage 85 to 270V AC/DC (AC: 50 or 60 Hz ) OPTIONAL - 24V AC/DC Power Consumption 5 VA max @230V AC Temperature Operating : -20 to 75°C Humidity (non-condensing) 95% RH Weight TC533AX:.