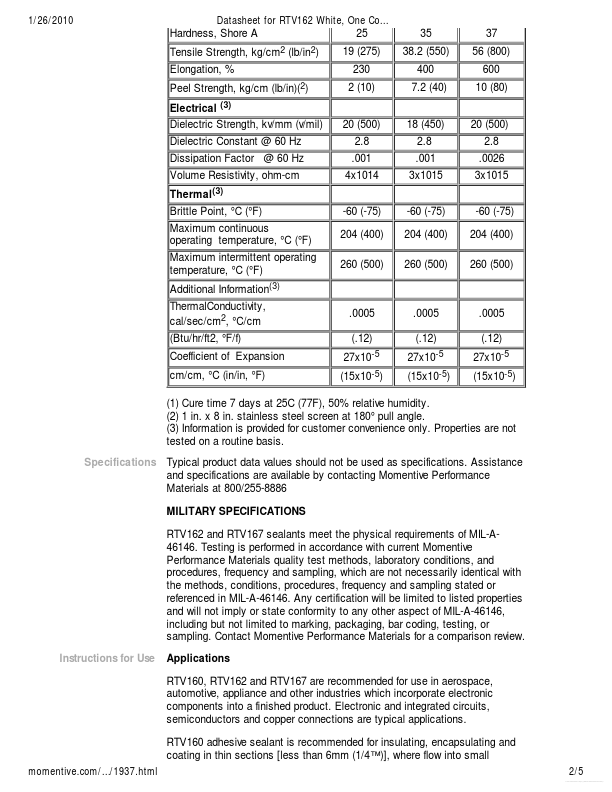

RTV162 Overview

RTV160, RTV162 and RTV167 adhesive sealants from Momentive Performance Materials are one-ponent, ready-to-use electronic grade silicone sealants. They cure to a tough, resilient silicone rubber on exposure to atmospheric moisture at room temperature. These electronic-grade silicone adhesive sealants differ somewhat in physical properties including consistency.