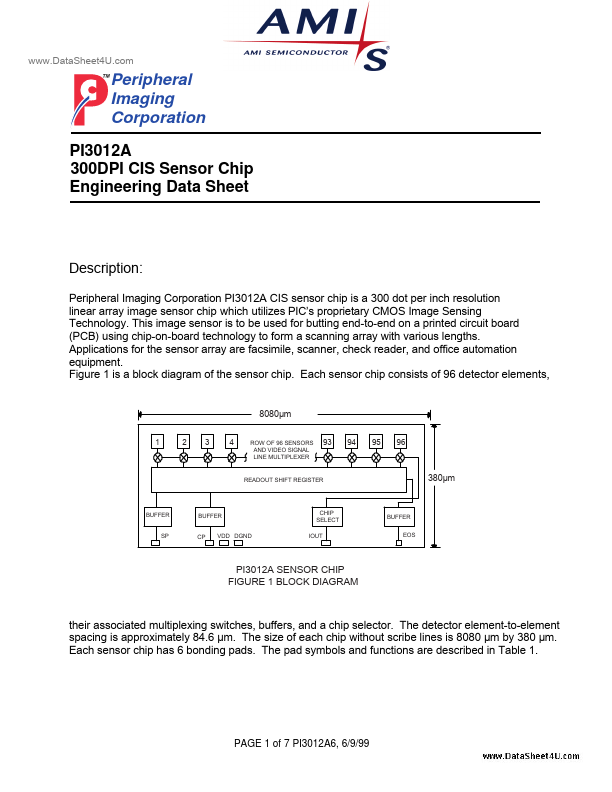

PI3012A Description

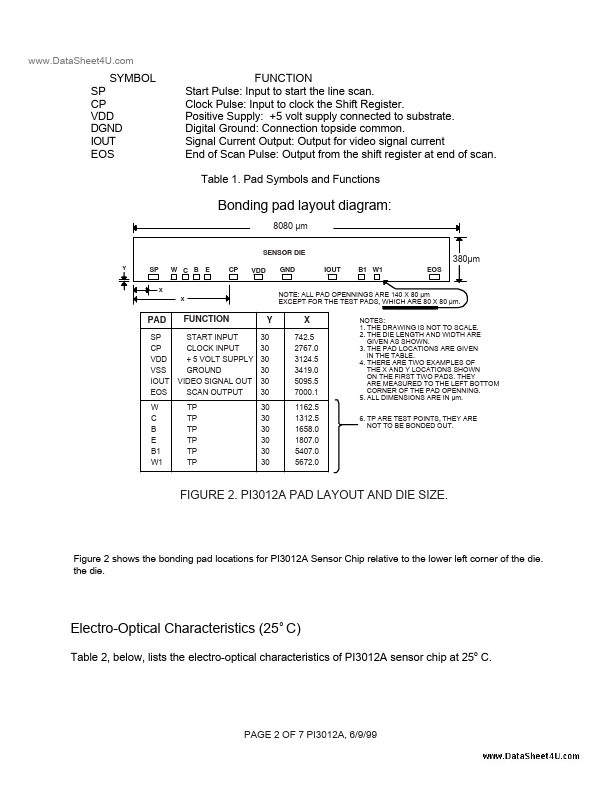

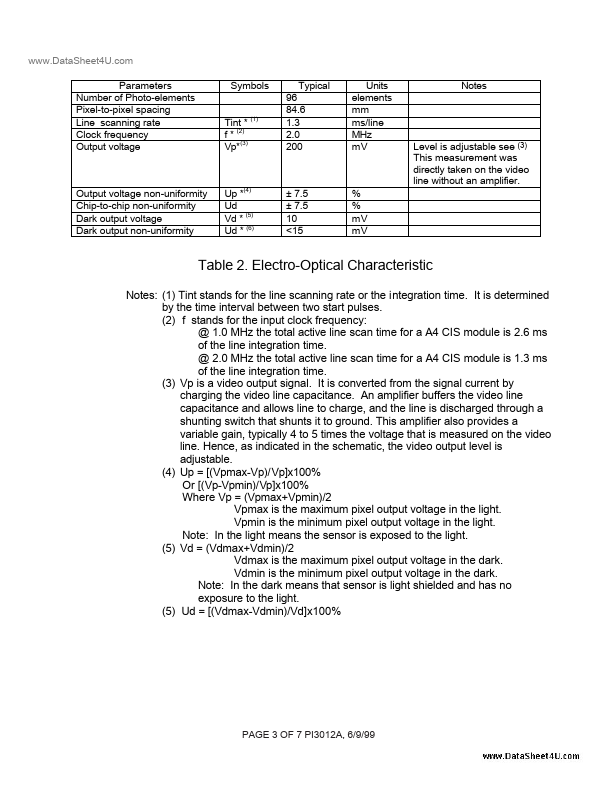

Peripheral Imaging Corporation PI3012A CIS sensor chip is a 300 dot per inch resolution linear array image sensor chip which utilizes PIC’s proprietary CMOS Image Sensing Technology. This image sensor is to be used for butting end-to-end on a printed circuit board (PCB) using chip-on-board technology to form a scanning array with various lengths. Applications for the sensor array are facsimile, scanner, check...